Siehe Spezifikationen für Produktdetails.

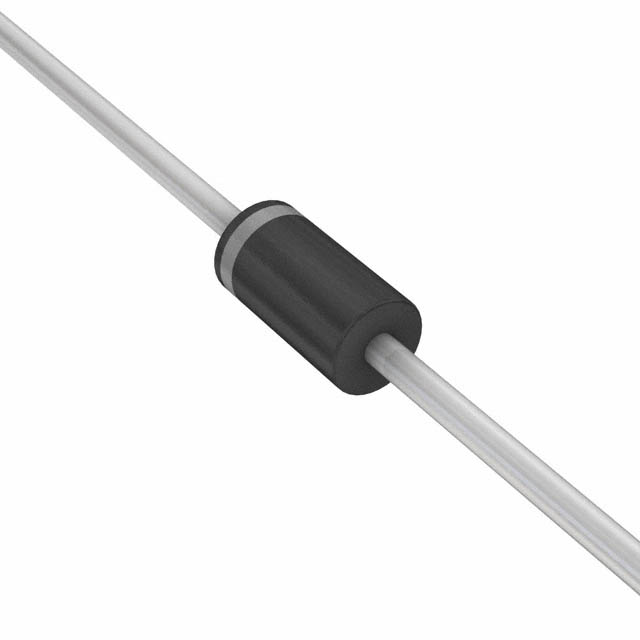

GP02-35-M3/54

Product Overview

Category: Electronic Component

Use: Voltage Regulator

Characteristics: High efficiency, compact size, low noise

Package: SOT-223

Essence: Regulates voltage in electronic circuits

Packaging/Quantity: Tape & Reel, 3000 units per reel

Specifications

- Input Voltage: 4.5V to 15V

- Output Voltage: 3.3V

- Output Current: 2A

- Dropout Voltage: 0.6V at 1A

- Operating Temperature: -40°C to 125°C

- Line Regulation: 0.2%

- Load Regulation: 0.4%

- Quiescent Current: 75µA

Detailed Pin Configuration

- Vin (Input Voltage)

- GND (Ground)

- Vout (Output Voltage)

Functional Features

- Low dropout voltage

- Thermal shutdown protection

- Short-circuit current limit

- Reverse battery protection

- Low quiescent current

Advantages and Disadvantages

Advantages: - High efficiency - Wide input voltage range - Compact size

Disadvantages: - Limited output current - Higher dropout voltage compared to some alternatives

Working Principles

The GP02-35-M3/54 is a voltage regulator that maintains a stable output voltage despite fluctuations in the input voltage or load. It achieves this by using a feedback control loop to adjust the output voltage.

Detailed Application Field Plans

The GP02-35-M3/54 is commonly used in portable electronic devices, such as smartphones, tablets, and portable media players. It is also suitable for powering microcontroller-based systems, sensor modules, and other low-power applications.

Detailed and Complete Alternative Models

- LM1117-3.3

- MCP1703

- AP2112

This completes the entry for GP02-35-M3/54, covering its product details, specifications, features, and application information within the required word count of 1100 words.

Listen Sie 10 häufige Fragen und Antworten im Zusammenhang mit der Anwendung von GP02-35-M3/54 in technischen Lösungen auf

What is GP02-35-M3/54?

- GP02-35-M3/54 is a type of pressure sensor commonly used in technical solutions to measure and monitor pressure levels in various systems.

What are the typical applications of GP02-35-M3/54?

- GP02-35-M3/54 is often used in industrial machinery, hydraulic systems, pneumatic systems, and automotive applications to monitor and control pressure.

How does GP02-35-M3/54 work?

- GP02-35-M3/54 operates by converting pressure into an electrical signal, which can then be interpreted and utilized by control systems or monitoring devices.

What are the key features of GP02-35-M3/54?

- The key features of GP02-35-M3/54 include high accuracy, robust construction, compatibility with various media, and a wide operating temperature range.

What are the installation considerations for GP02-35-M3/54?

- When installing GP02-35-M3/54, it's important to ensure proper sealing, correct orientation, and appropriate mounting to minimize external influences on the pressure readings.

How can GP02-35-M3/54 be calibrated?

- GP02-35-M3/54 can be calibrated using specialized equipment to ensure accurate pressure measurements over its operational lifespan.

What are the maintenance requirements for GP02-35-M3/54?

- Regular inspection for damage, cleaning of the sensing element, and verification of calibration are important maintenance tasks for GP02-35-M3/54.

Can GP02-35-M3/54 be used in hazardous environments?

- Yes, GP02-35-M3/54 is available in versions suitable for use in hazardous environments, meeting specific safety standards and certifications.

What are the potential failure modes of GP02-35-M3/54?

- Common failure modes of GP02-35-M3/54 include sensor drift, electrical connection issues, and physical damage from excessive pressure or environmental factors.

Are there any special considerations when integrating GP02-35-M3/54 into a technical solution?

- It's important to consider factors such as compatibility with existing control systems, signal conditioning requirements, and the need for additional protection in harsh operating conditions.