Siehe Spezifikationen für Produktdetails.

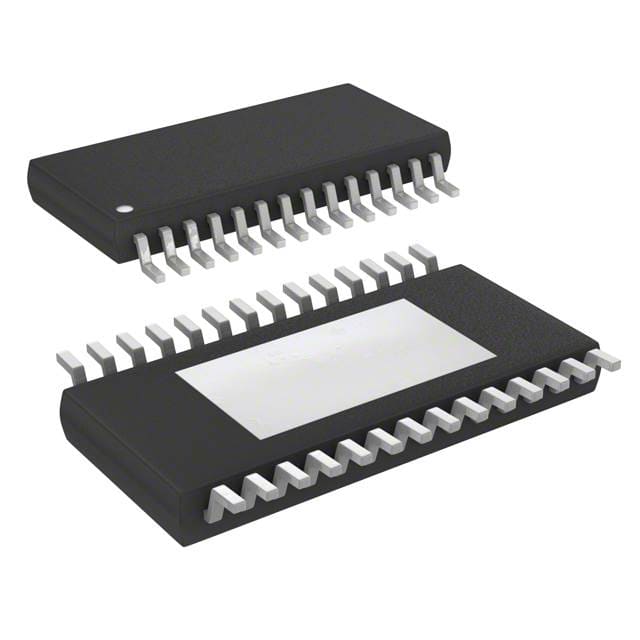

MAX31911AUI+T

Product Overview

- Category: Integrated Circuit (IC)

- Use: Signal Conditioning

- Characteristics: High-speed, low-power, robust communication interface

- Package: 28-pin TSSOP (Thin Shrink Small Outline Package)

- Essence: Signal conditioning IC for industrial applications

- Packaging/Quantity: Tape and Reel, 2500 units per reel

Specifications

- Supply Voltage Range: 3.0V to 3.6V

- Operating Temperature Range: -40°C to +125°C

- Communication Interface: SPI (Serial Peripheral Interface)

- Data Rate: Up to 50 Mbps

- Number of Channels: 4 differential or 8 single-ended inputs

- Input Voltage Range: ±25V

- Input Common-Mode Voltage Range: -25V to +25V

- Output Voltage Range: 0V to VCC

- Output Current: ±10mA

Pin Configuration

The MAX31911AUI+T has a total of 28 pins. The pin configuration is as follows:

- IN1P: Input 1 Positive Differential

- IN1N: Input 1 Negative Differential

- IN2P: Input 2 Positive Differential

- IN2N: Input 2 Negative Differential

- IN3P: Input 3 Positive Differential

- IN3N: Input 3 Negative Differential

- IN4P: Input 4 Positive Differential

- IN4N: Input 4 Negative Differential

- GND: Ground

- VCC: Power Supply

- SDI: Serial Data Input

- SDO: Serial Data Output

- SCLK: Serial Clock Input

- CS: Chip Select

- EN: Enable

- FLT: Fault Indicator

- REF: Reference Voltage Output

- VCCIO: I/O Power Supply

- OUT1: Output 1

- OUT2: Output 2

- OUT3: Output 3

- OUT4: Output 4

- NC: No Connection

- NC: No Connection

- NC: No Connection

- NC: No Connection

- NC: No Connection

- NC: No Connection

Functional Features

- High-speed, low-power signal conditioning for industrial applications

- Robust communication interface with built-in fault detection and reporting

- Flexible input configuration supporting both differential and single-ended inputs

- Wide input voltage range and common-mode voltage range for versatile signal conditioning

- SPI interface for easy integration with microcontrollers and other digital devices

- Fault indicator pin for monitoring the status of the device

- Reference voltage output for external use

Advantages and Disadvantages

Advantages: - High-speed data transmission up to 50 Mbps - Low power consumption for energy-efficient operation - Robust communication interface ensures reliable data transfer - Versatile input configuration supports various signal types - Wide input voltage range accommodates different signal levels

Disadvantages: - Limited number of channels (4 differential or 8 single-ended inputs) - Requires external microcontroller or digital device for full functionality - Relatively high cost compared to simpler signal conditioning solutions

Working Principles

The MAX31911AUI+T is designed to condition and process analog signals in industrial applications. It provides a robust communication interface between sensors, actuators, and microcontrollers. The IC accepts differential or single-ended input signals, amplifies and filters them, and converts them into digital data using an internal ADC (Analog-to-Digital Converter). The digital data is then transmitted through the SPI interface to a microcontroller or other digital devices for further processing.

The device operates on a supply voltage range of 3.0V to 3.6V and can withstand a wide temperature range from -40°C to +125°C, making it suitable for harsh industrial environments. It features built-in fault detection and reporting, allowing the system to monitor the integrity of the signal conditioning process. The fault indicator pin provides a visual indication of any detected faults.

Detailed Application Field Plans

The MAX31911AUI+T is commonly used in various industrial applications that require reliable signal conditioning. Some of the specific application fields include:

Process Control Systems: The IC is used to condition sensor signals in industrial process control systems, such as temperature, pressure, and flow monitoring. It ensures accurate and reliable data acquisition for precise control and monitoring.

Motor Control: In motor control applications, the IC helps in conditioning feedback signals from encoders or sensors, enabling precise control of motor speed, position, and torque. It enhances the overall performance and efficiency of motor control systems.

Industrial Automation: The device finds application in automation systems where it conditions signals from different sensors and actuators, facilitating seamless communication

Listen Sie 10 häufige Fragen und Antworten im Zusammenhang mit der Anwendung von MAX31911AUI+T in technischen Lösungen auf

Sure! Here are 10 common questions and answers related to the application of MAX31911AUI+T in technical solutions:

Q: What is the MAX31911AUI+T? A: The MAX31911AUI+T is a high-speed, low-power transceiver designed for RS-485/RS-422 communication.

Q: What is the maximum data rate supported by the MAX31911AUI+T? A: The MAX31911AUI+T supports data rates up to 25Mbps.

Q: Can the MAX31911AUI+T be used in half-duplex mode? A: Yes, the MAX31911AUI+T can be configured for both half-duplex and full-duplex operation.

Q: What is the operating voltage range of the MAX31911AUI+T? A: The MAX31911AUI+T operates from a single 3.0V to 5.5V supply voltage.

Q: Does the MAX31911AUI+T have built-in protection features? A: Yes, the MAX31911AUI+T includes features like short-circuit protection and thermal shutdown to ensure robust operation.

Q: Can the MAX31911AUI+T be used in industrial environments? A: Yes, the MAX31911AUI+T is designed to operate in harsh industrial environments with extended temperature ranges.

Q: How many receivers can be connected to the MAX31911AUI+T? A: The MAX31911AUI+T can support up to 256 receivers on a bus.

Q: Is the MAX31911AUI+T compatible with other RS-485/RS-422 transceivers? A: Yes, the MAX31911AUI+T is compatible with other standard RS-485/RS-422 transceivers.

Q: Does the MAX31911AUI+T support hot-swapping of devices? A: Yes, the MAX31911AUI+T supports hot-swapping, allowing for easy replacement or addition of devices on the bus.

Q: Are there any evaluation kits available for the MAX31911AUI+T? A: Yes, Maxim Integrated provides evaluation kits that include the MAX31911AUI+T and necessary software for testing and development.

Please note that these answers are general and may vary depending on specific application requirements. It's always recommended to refer to the datasheet and application notes for detailed information.