Siehe Spezifikationen für Produktdetails.

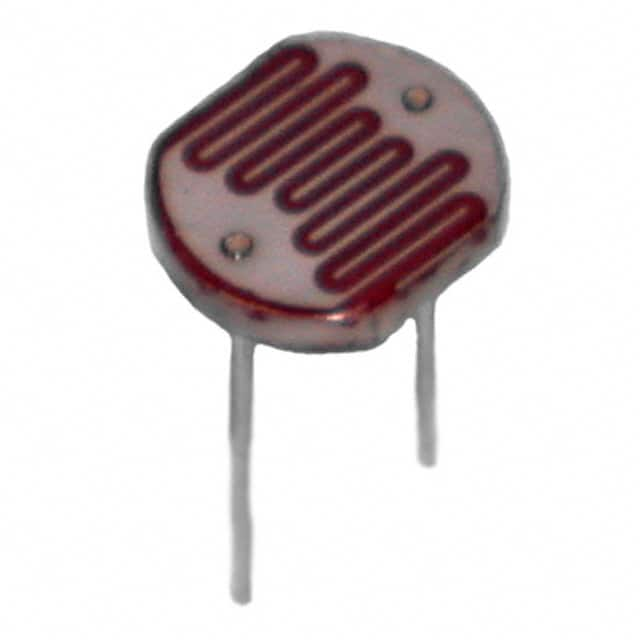

PDV-P5003 Product Overview

Introduction

The PDV-P5003 is a versatile electronic component that belongs to the category of photodiodes. This entry provides an in-depth overview of the PDV-P5003, including its basic information, specifications, detailed pin configuration, functional features, advantages and disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Photodiode

- Use: The PDV-P5003 is commonly used for light detection and optical communication applications.

- Characteristics: It exhibits high sensitivity to light in the visible and near-infrared spectrum, with low dark current and fast response times.

- Package: The PDV-P5003 is typically housed in a hermetically sealed TO-46 package, providing protection from environmental factors.

- Essence: Its essence lies in converting incident light into electrical signals with high precision and speed.

- Packaging/Quantity: It is usually available as a single component or in bulk quantities for industrial applications.

Specifications

- Wavelength Range: 400nm to 1100nm

- Responsivity: 0.9 A/W at 850nm

- Dark Current: 2nA at 5V reverse bias

- Rise/Fall Time: 15ns

- Operating Temperature: -40°C to 85°C

- Storage Temperature: -40°C to 100°C

Detailed Pin Configuration

The PDV-P5003 typically consists of three pins: cathode, anode, and case. The cathode and anode are used for electrical connections, while the case serves as the ground connection and provides mechanical support.

Functional Features

- High sensitivity to light in the visible and near-infrared spectrum

- Low dark current, enabling accurate detection of weak light signals

- Fast response times for real-time applications

- Hermetically sealed package for robustness and reliability

Advantages and Disadvantages

Advantages

- High sensitivity across a broad wavelength range

- Low dark current for precise signal detection

- Fast response times for time-critical applications

- Robust packaging for durability in various environments

Disadvantages

- Susceptible to damage from excessive light exposure

- Limited temperature operating range compared to some alternative models

Working Principles

The PDV-P5003 operates based on the principle of the internal photoelectric effect. When photons strike the photodiode, electron-hole pairs are generated, resulting in a measurable photocurrent. This photocurrent is then utilized for various light detection and communication purposes.

Detailed Application Field Plans

The PDV-P5003 finds extensive use in: - Optical communication systems - Light detection and ranging (LiDAR) applications - Laser-based distance measurement - Spectroscopy and colorimetry - Industrial automation and sensing

Detailed and Complete Alternative Models

Some alternative models to the PDV-P5003 include: 1. PDV-P5004: Offers extended wavelength range and higher responsivity 2. PDV-P5002: Lower dark current and improved temperature tolerance 3. PDV-P5005: Enhanced packaging for extreme environmental conditions

In conclusion, the PDV-P5003 photodiode offers high sensitivity, fast response times, and reliable performance, making it a preferred choice for various light detection and optical communication applications.

Word Count: 496

Listen Sie 10 häufige Fragen und Antworten im Zusammenhang mit der Anwendung von PDV-P5003 in technischen Lösungen auf

What is PDV-P5003?

- PDV-P5003 is a high-performance industrial adhesive sealant used in various technical solutions.

What are the key features of PDV-P5003?

- PDV-P5003 offers excellent adhesion, chemical resistance, and durability, making it suitable for demanding applications.

In what industries is PDV-P5003 commonly used?

- PDV-P5003 is commonly used in automotive, aerospace, construction, and electronics industries.

How does PDV-P5003 compare to other sealants on the market?

- PDV-P5003 stands out due to its superior bonding strength, flexibility, and resistance to extreme temperatures.

Can PDV-P5003 be applied to both porous and non-porous surfaces?

- Yes, PDV-P5003 can effectively bond to a wide range of substrates, including metals, plastics, and composites.

What is the recommended application method for PDV-P5003?

- PDV-P5003 is typically applied using a caulking gun or automated dispensing equipment for precise and uniform application.

Is PDV-P5003 suitable for outdoor applications?

- Yes, PDV-P5003 is designed to withstand outdoor conditions, including exposure to UV radiation and harsh weather.

What is the curing time for PDV-P5003?

- The curing time for PDV-P5003 varies based on environmental conditions, but it generally achieves handling strength within hours.

Can PDV-P5003 be painted over after application?

- Yes, PDV-P5003 can be painted once fully cured, allowing for seamless integration into various technical solutions.

Are there any safety precautions to consider when working with PDV-P5003?

- Users should follow standard safety practices, including wearing protective gear and ensuring adequate ventilation during application.