Siehe Spezifikationen für Produktdetails.

CPC15AH Product Overview

Introduction

CPC15AH is a versatile electronic component that belongs to the category of solid-state relays. This product is widely used in various applications due to its unique characteristics and functional features. In this entry, we will provide an overview of CPC15AH, including its basic information, specifications, pin configuration, functional features, advantages, disadvantages, working principles, application field plans, and alternative models.

Basic Information Overview

- Category: Solid-State Relay

- Use: Control and switching of electrical loads

- Characteristics: High reliability, fast switching speed, compact design

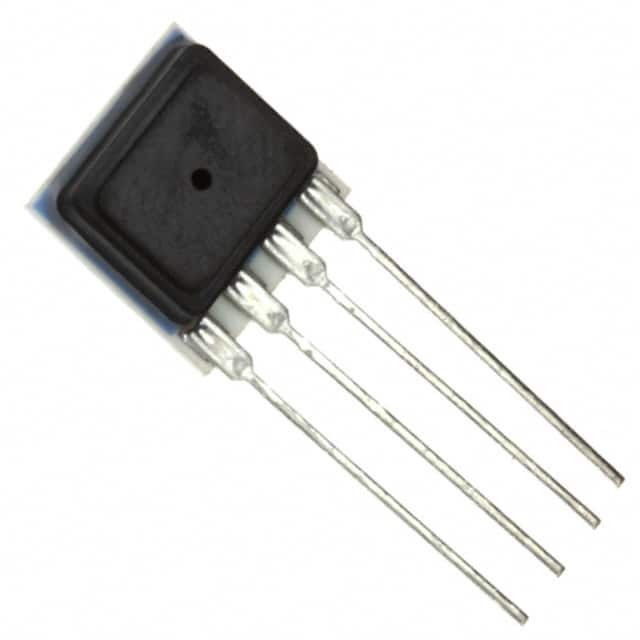

- Package: DIP (Dual Inline Package)

- Essence: Efficient and reliable control of electrical circuits

- Packaging/Quantity: Typically available in packs of 10 or 25 units

Specifications

- Input Voltage Range: 3V to 32V DC

- Load Voltage Range: 24V to 380V AC

- Load Current Capacity: Up to 15A

- Isolation Voltage: 2500Vrms

- Operating Temperature Range: -40°C to 85°C

- On-State Voltage Drop: Typically 1.5V at 15A

Detailed Pin Configuration

The CPC15AH solid-state relay typically features the following pin configuration: - Pin 1: Input Control Terminal - Pin 2: Input Control Terminal - Pin 3: Load Output Terminal - Pin 4: Load Output Terminal

Functional Features

- Fast Switching: The CPC15AH offers rapid switching capabilities, making it suitable for applications requiring quick response times.

- High Reliability: With no moving parts, the solid-state relay provides enhanced reliability and longevity compared to traditional electromechanical relays.

- Opto-Isolation: The input and output circuits are optically isolated, providing improved safety and noise immunity.

Advantages and Disadvantages

Advantages

- Compact Design: The DIP package allows for space-efficient PCB mounting.

- Noise-Free Operation: Solid-state relays produce minimal electromagnetic interference.

- Long Lifespan: The absence of mechanical components contributes to a longer operational life.

Disadvantages

- Heat Dissipation: Under high load currents, heat dissipation may be a concern and requires proper thermal management.

- Cost: Solid-state relays can be more expensive than traditional relays, especially for high-current applications.

Working Principles

The CPC15AH operates based on the principle of using semiconductor devices, such as thyristors or triacs, to switch the load current without the need for mechanical contacts. When an appropriate control signal is applied to the input terminals, the internal semiconductor switch turns on, allowing current to flow through the load circuit.

Detailed Application Field Plans

The CPC15AH solid-state relay finds extensive use in various applications, including: - Industrial Automation: Control of motors, heaters, and solenoids in manufacturing processes. - HVAC Systems: Switching of heating elements and fans in heating, ventilation, and air conditioning systems. - Lighting Control: Dimming and switching of lighting circuits in commercial and residential settings.

Detailed and Complete Alternative Models

Several alternative models to CPC15AH include: - CPC10AH: A lower current capacity version suitable for lighter loads. - CPC20AH: A higher current capacity version for heavy-duty applications. - CPC15BH: A variant with enhanced thermal management capabilities for high-temperature environments.

In conclusion, the CPC15AH solid-state relay offers a reliable and efficient solution for controlling electrical loads in diverse applications. Its fast switching speed, high reliability, and compact design make it a preferred choice for many electronic systems.

Word Count: 554

Listen Sie 10 häufige Fragen und Antworten im Zusammenhang mit der Anwendung von CPC15AH in technischen Lösungen auf

What is CPC15AH?

- CPC15AH is a high-performance, thermally conductive compound used for heat dissipation in electronic devices.

How does CPC15AH work?

- CPC15AH works by filling gaps and irregularities between heat-generating components and heat sinks, allowing for efficient transfer of heat away from the electronic device.

What are the key properties of CPC15AH?

- CPC15AH has high thermal conductivity, low thermal resistance, and excellent stability over a wide temperature range.

Where can CPC15AH be applied?

- CPC15AH can be applied in various electronic devices such as CPUs, GPUs, power supplies, LED lighting, and other heat-generating components.

Is CPC15AH electrically conductive?

- No, CPC15AH is non-electrically conductive, making it safe to use in electronic applications without risk of short circuits.

How should CPC15AH be applied?

- CPC15AH should be applied in a thin, uniform layer between the heat source and the heat sink using a spatula or dispensing equipment.

What is the recommended curing time for CPC15AH?

- The recommended curing time for CPC15AH is typically 24 hours at room temperature, but it may vary based on application and environmental conditions.

Can CPC15AH be used in outdoor applications?

- Yes, CPC15AH is suitable for outdoor applications due to its excellent stability over a wide temperature range.

Does CPC15AH require any special handling precautions?

- It is recommended to avoid skin contact with CPC15AH and to use it in well-ventilated areas due to its chemical composition.

Are there any alternative products to CPC15AH?

- Yes, there are alternative thermal compounds available, but CPC15AH is preferred for its high performance and reliability in technical solutions.